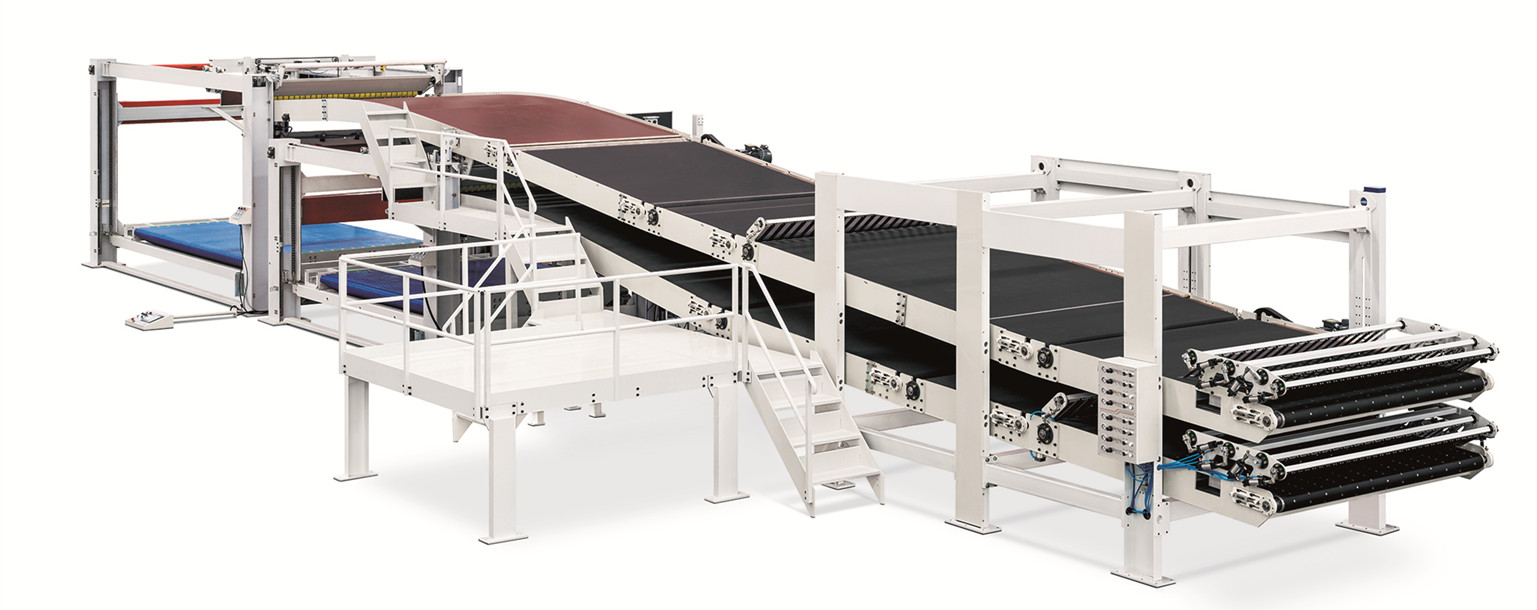

Automatic double layer down stacker could be able to complete board stacking, counting, batching, stacking and automatic transverse discharge etc. The basket is provided with balance weight to improve mechanical efficiency and reduce energy consumption. With high efficiency servo control, the running speed of basket could be improved, and the circulating period of stack changing is shortened. Thereby it can benefit high speed production and small orders.

Electric and pneumatic part

PHASE AC Servo Motor/Inovance servo motor

Shanghai Futian VF Motor

Pneumatic components from SMC, Air Tac

Actuation Part

High quality steel frames

Conveying rollers made of high-quality seamless steel tube, and subject to

dynamic balance checking;

Switzerland Rapplon conveying belt

Module conveyor belt imported from Denmark

Transmission Part

Imported synchronous belt transmission

HRB precision bearings

Imported coupling

Control Part

The control of ascending and descending the basket platform: Servo control

The control of conveying segment: Schneider frequency converter

Rear baffle positioning Control: servo control

Transverse discharge Control: Schneider VF control

Operation Monitoring: Schneider touch screen

Monitoring Control: Schneider PLC, Sick series sensor

Low-voltage Apparatus: Schneider

he upper and lower layer suspension basket stacker could operate for each layer to realize the

stacking of two specifications of boards.

The upper layer is consisted of five section conveyors and the lower layer is four sections. They are

controlled by frequency converter and could be synchronized with the production line automatically. The

speed could be automatically adjusted during stacking change and order change to ensure smooth and

reliable running.

The stacking is controlled by servo motor. The suspension basket could be run stably and boards are

stacked neatly.

With transverse discharge module belt structure, the boards could be automatically and transversely

discharged when a preset number is reached.

The back baffle is controlled by AC servo motor to complete automatic adjustment as per settings and

realize fast order change. The baffle could be automatically lifted or translated to realize multi-order

stacking.

Optical device of back baffle could actually measure board surface height.

Board-feeding section uses four groups of steel strip type reducing structure which cooperates with

vacuum absorbing belt conveying to ensure boards are stacked neatly; four groups of steel strip are

used for pressing paper to adjust pressing state automatically according to length of boards.

The rotary batch separating mandril is provided between section 1 and 2 to accurately count, batch

as per the sheet number set by system to ensure correct stacking.

The board conveying belt is guided by guide strip and easy to adjust and serve for a longer life.

The up and down stacker is equipped with color touching interface which is easy to operate.

Matching up the module conveying platform, the board stacks could be transported automatically and

fast to logistics wharfs.